Reducing the risk of human exposure

Used in the production of aluminum, fluorocarbons and gasoline and for applications like glass etching and uranium processing, hydrofluoric acid is an extremely dangerous chemical that must be handled with the utmost care.

- This corrosive liquid penetrates tissue more quickly than typical acids. Toxicity can occur through dermal, ocular, inhalation and oral routes.

- Since HF alters nerve function, accidental exposure can go unnoticed by the victim, delaying treatment and increasing the extent of injury.

- It can also be absorbed by the blood through the skin, reacting with blood calcium and potentially causing a heart attack.

The extreme nature of this chemical calls for superior structural integrity – the level of integrity Poly Processing is known for.

The Poly Processing Hydrofluoric Acid System

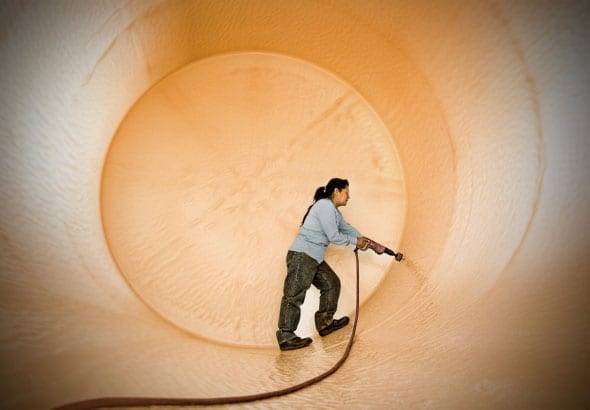

When people’s lives are at risk, you can take no chances. You need a system that goes above and beyond to prevent contact with this corrosive acid. That system starts with a crosslinked polyethylene tank. XLPE is a thermoset resin that gives customers 20 times the environmental stress-crack resistance, 10 times the molecular weight and 5 times the impact and tensile strength of HDPE. This system carries a warranty for a full five years.

A SAFE-Tank® can help reduce health and environmental concerns due to closed containment of hydrofluoric acid.

If a SAFE-Tank® is not a possibility, an IMFO® flange can be used to reduce hands-on maintenance, thereby reducing the risk to your employees.